Benefits of Perforated Panels in Engineering

Perforated Panels

Perforated panels offer a multitude of benefits in various engineering applications. Their inherent design, characterized by regularly spaced apertures, allows for controlled passage of air, light, and sound. This permeability makes them invaluable for ventilation systems, acoustic dampening, and aesthetic lighting solutions. Structurally, engineers can tailor the perforation pattern to optimize strength-to-weight ratios, leading to efficient material usage in construction and aerospace engineering. Furthermore, perforated panels facilitate effective filtration and screening, finding use in diverse industries ranging from agriculture to chemical processing. Their versatility, coupled with ease of manufacturing and installation, renders perforated panels a cost-effective and adaptable solution for a wide spectrum of engineering challenges.

The Role of Perforated Panels in Modern Engineering

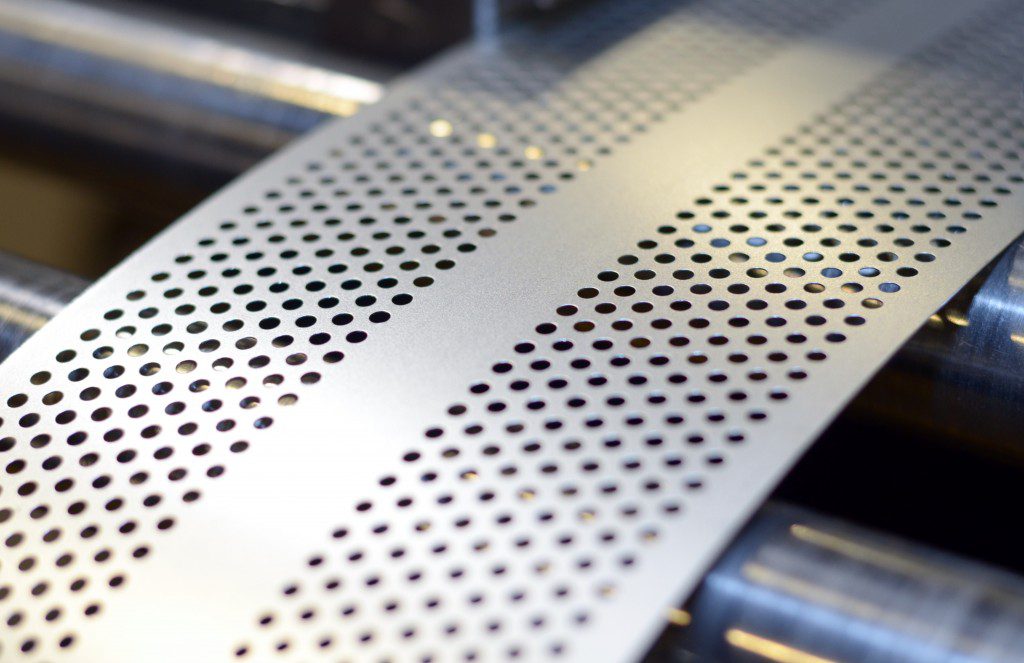

Perforated panels offer a multitude of benefits in various engineering applications, stemming from their unique combination of structural integrity, functional versatility, and aesthetic appeal. Their widespread adoption across diverse industries underscores their significance as a valuable engineering material.

One of the primary advantages of perforated panels is their ability to provide ventilation and airflow. The perforations, strategically designed and sized, allow for the passage of air, making them ideal for applications such as HVAC systems, enclosures for electronic equipment, and architectural facades. This enhanced airflow can improve thermal management, prevent overheating, and contribute to energy efficiency.

Furthermore, architects and engineers frequently employ perforated panels for their acoustic properties. The perforations act as sound absorbers, reducing noise levels and reverberation within enclosed spaces. This makes them suitable for use in noise barriers, acoustic panels in auditoriums and studios, and silencers for industrial machinery. You can tailor the specific acoustic performance by adjusting the perforation size, pattern, and panel thickness.

The Functional and Aesthetic Advantages of Perforated Panels in Engineering

In terms of structural engineering, perforated panels offer a balance of strength and weight reduction. Designers can create perforations that maintain structural integrity while minimizing the overall weight of the panel. This is particularly advantageous in applications where weight is a critical factor, such as aerospace components, automotive parts, and lightweight building structures. The strategic placement of perforations can also enhance the panel’s resistance to bending and buckling.

Beyond their functional benefits, perforated panels also offer aesthetic flexibility. The perforations can be arranged in various patterns, creating visually appealing designs. They can be used as decorative elements in architectural facades, interior design, and product design. The panels can also be finished in a wide range of colors and materials, further enhancing their aesthetic versatility.

In conclusion, perforated panels provide a compelling combination of functional and aesthetic benefits in engineering applications. Their ability to facilitate ventilation, reduce noise, offer structural integrity with weight reduction, and provide aesthetic flexibility makes them a versatile and valuable material for engineers across diverse industries. As technology advances, the design and application of perforated panels are likely to evolve further, expanding their role in innovative engineering solutions.

To Learn About 4 Benefits Of Perforated Metal Panels In Modern Architecture, Click Here.